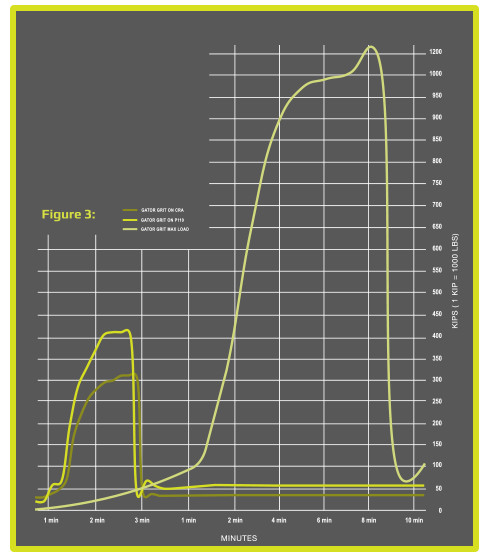

Increased Load Capacity

Increased load capacity. During our testing process, we loaded Gator Grit inserts to the maximum yield strength, 170 tons, of both chrome and P110 pipe. That benchmark was met with ease and got us curious to what kind of max load Gator Grit was capable of. A solid mandrel was loaded into the test fixture and 650 tons were held easily before the slip began to fail. Gator Grit dies and inserts are proven to outlast the maximum yields of both pipe and slip.

Durability of Inserts

Durability of inserts. With a coating hardness of 72HRC, Gator Grit dies and inserts have the ability to last significantly longer by maintaining their structure and dulling less frequently than traditional dies and inserts. The increased durability gives operators a new solution for handling harder pipe where most dies and inserts flatten out quickly.

Our competition may have set the standard. Gator Grit just changed the game!

Grip it. Twist it. Lift it.

With today's mindset of harvesting resources where they can be found, oil and gas drilling operators have found themselves deep into highly corrosive environment. The presence of H2S gases and other reactants have made it extremely difficult to reach the deposits located within the volatile environments. As technology progresses, we give ourselves the ability to adapt to these conditions and make what was once a pipe dream a strong reality.

With the introduction of CRA (Corrosion Resistant Alloy) tubulars, we have given ourselves the upper hand at reaching these previously untapped deposits, however the technology should not stop there. Wherever there is a new way there is a higher cost and that has never been more evident than with CRA tubulars. With such a sizable investment tied up in these new age pipes, we have to rethink the way we handle them or risk chewing right through the profits.

Rig Tool Products was put to task to help find a way that would not only extended the life of the pipe itself, but also yield a higher load capacity as well. Our answer, Gator Grit.

Safe for Sour Gas Wells

Safe for Sour Gas Wells. Gator grit inserts are coated with a proprietary alloy specifically designed to not introduce any materials that would aid in the corrosion or breaking down of pipe in corrosive environments.

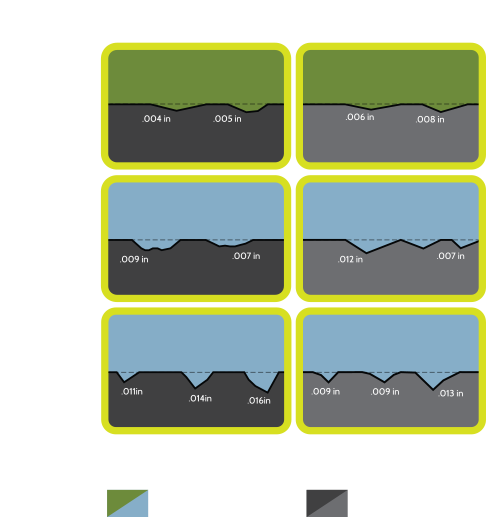

Decreased Depth of Penetration

Decreased marking and pitting on pipe. The dynamic nature of the coating for random patterns thus utilizing more of the pipe surface for gripping.

Decreased depth of penetration. When tested on chrome pipe (SM13CRM-110), Gator Grit's measurable depth of penetration was 50% less than traditional inserts and 25% less than the leading competitor!